Oil Removal & Recovery

Danat Saudia is helping its customers to fully participate in the Saudi Circular Economy. Through our work with SIRC, and leading technologies across the globe, we are able to offer treatment solutions that not only remove costly hydrocarbons from water but also can recover these contaminants to become valuable recycled products. Our advanced oil removal systems, including primary separators, coalescers, hydrocyclones, and industry-leading regenerable filter medias, are designed to not only remove emulsified and free-phase hydrocarbons down to 4 micron level, but also to recover them with high purity. We are also able to separate out drilling mud and challenging tank bottom materials to recover the water, oil and mud separately. By converting waste oil streams into usable fuel or saleable byproducts, our clients can turn a costly liability into a profitable resource, in line with the Kingdom's Vision 2030 goals for industrial sustainability and resource efficiency.

We have deployed oil recovery solutions across a range of industries, including upstream, petrochemical, refining, and waste management. In one standout project, Danat’s treatment system recovered hundreds of tonnes of high-purity hydrocarbons from a degasser unit stream that previously contaminated the client's entire wastewater system. Our ability to isolate and treat these concentrated streams not only allowed the facility to resume compliant discharge but also generated significant revenue from the recovered product—transforming "waste to worth" in the truest sense.

By focusing on point-source contamination control and oil recovery at the earliest stages of water generation, Danat enables facilities to enhance their production, reduce downtime, optimize their water treatment infrastructure, and align operations with global best practices.

Danat Saudia’s Advantages

Rapid Response

Danat Saudia maintains a Rapid Response fleet of equipment to support clients with their emergency situations

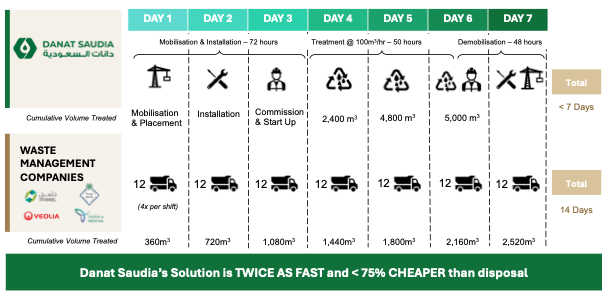

Danat Saudia’s Rapid Response can be mobilised and installed within 72 hours and within the first day of operation will have treated more than disposal by truck alternative running for four days.

No contamination too high

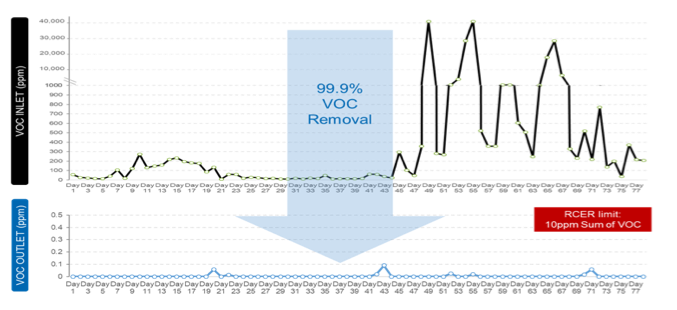

Danat Saudia is able to handle the highest contamination loading in process and waste water in Saudi Arabia

Perfectly suited for excursions during operation or during turnarounds

Outlet from Danat Saudia systems are reliably onspec to ensure no delay or shutdown due to water treatment

Best in Class Technology

Danat Saudia has exclusive access to the best available technology for oil recovery and reuse

The latest Advanced Coalescer is a simple design, powered by gravity, has no moving parts, requires no level controllers or gas demand and generates no froth or entrained gas

The MAC 2.0 is a highly efficient 3-Phase Separator

95% removal efficiency of free oil droplets larger than 35 µm

90% removal efficiency and concentration of solids larger than 30 µm at SG >1.8

No sheer, minimizes emulsions

No chemicals required

Delivers separated oil at <5% Base Solids in Water

Delivers heavy solids at 8%solids (mass) concentration slurry